Compressor and Pumps

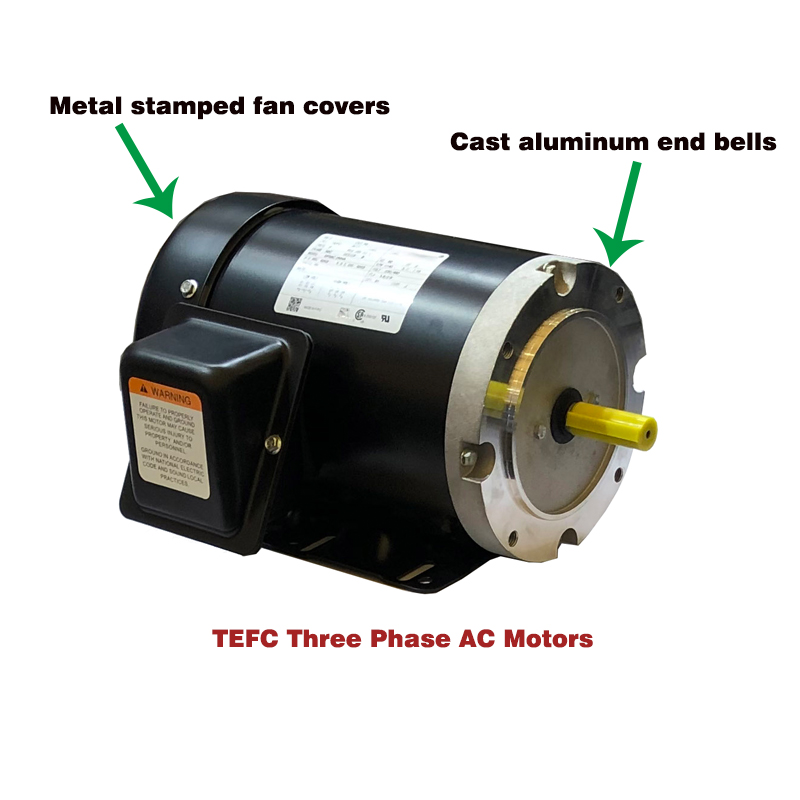

Air compressor motors must be designed to provide reliable and efficient operation in a wide range of environments. Some of the key requirements for air compressor motors include:

High Starting Torque: Air compressors require high starting torque to overcome the resistance of the compressor pump. Motors with high starting torque ensure that the compressor starts quickly and efficiently.

Continuous Duty: Air compressor motors must be designed for continuous duty, as compressors often run for extended periods of time. Motors that are not designed for continuous duty may overheat and fail prematurely.

Efficient Operation: Air compressor motors must be designed for efficient operation, as compressors consume a significant amount of energy. Motors that are designed for high efficiency can help reduce energy consumption and operating costs.

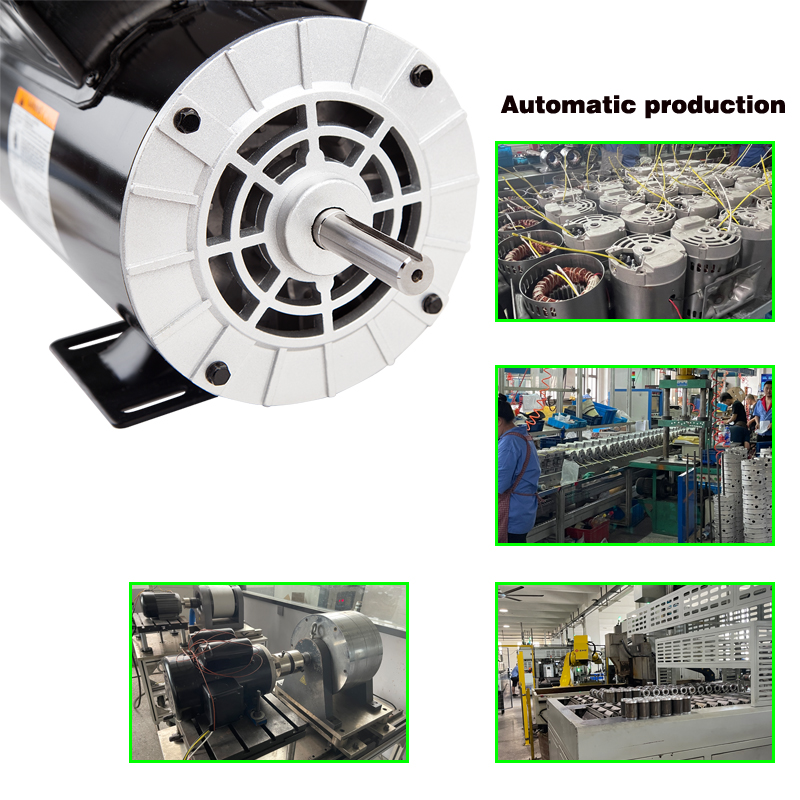

Robust Construction: Air compressor motors must be built with durable materials that can withstand the harsh environments commonly found in compressor applications. Motors with robust construction can help ensure reliable and long-lasting operation.

Low Noise and Vibration: Air compressor motors should be designed for low noise and vibration, as excessive noise and vibration can be a nuisance and impact nearby equipment and personnel.

Overall, air compressor motors must be designed to meet the specific requirements of compressor applications, providing reliable and efficient operation while withstanding harsh environments.

NEMA Series TEFC 56 Single Phase Jet Pump Motor

Rolled Steel NEMA 56Y Swimming Pool Pump Motor

General purpose use on commericial & industrial pumps centrifugal and hydraulic pumps. machine tools. and other equipments requiring NEMA C-face 48Y, 56Y 56J mounting configuration

Used on many Sta-Rite, Red Jacket, Pac Fab, American Products and Sears jet and pool pumps3450 RPM, rotation is CCW pump end Stainless steel — 303 threaded shaft, thermal protector Sealed ball bearings, open dripproof construction When replacing this type of motor total output (HP x Service Factor) must equal or exceed motor being replaced, Resistance start

The magnetic gear pumps are designed for low flow rate applications, with flow rates ranging from 20ml/min to 51000ml/min. Our expertise lies in applications such as conveying, dosing, lubrication, sampling, spraying, dispensing, printing, pressurizing, filtering, cleaning, circulation, coating, painting, and metering, among others

Precise Flow Control: Micro gear pumps offer precise flow control, making them ideal for applications that require accurate dosing or dispensing of fluids.

Compact Size: Micro gear pumps are small and compact, making them ideal for use in tight spaces or applications that require a small footprint.

Low Power Consumption: Micro gear pumps are designed to consume a low amount of power, making them energy-efficient and cost-effective.

High Efficiency: Micro gear pumps are highly efficient, providing reliable and consistent performance while minimizing waste or product loss.

Self-Priming: Micro gear pumps are self-priming, meaning they can operate without the need for external priming or filling.

Low Noise and Vibration: Micro gear pumps operate quietly and with low vibration, making them ideal for use in sensitive environments or applications where excessive noise or vibration could be disruptive.

Overall, micro gear pumps offer precision, efficiency, compact size, and low power consumption, making them an ideal solution for a wide range of applications, from medical devices to industrial automation.