How to Select a Gear Motors for your project

2023-10-07Updated on:

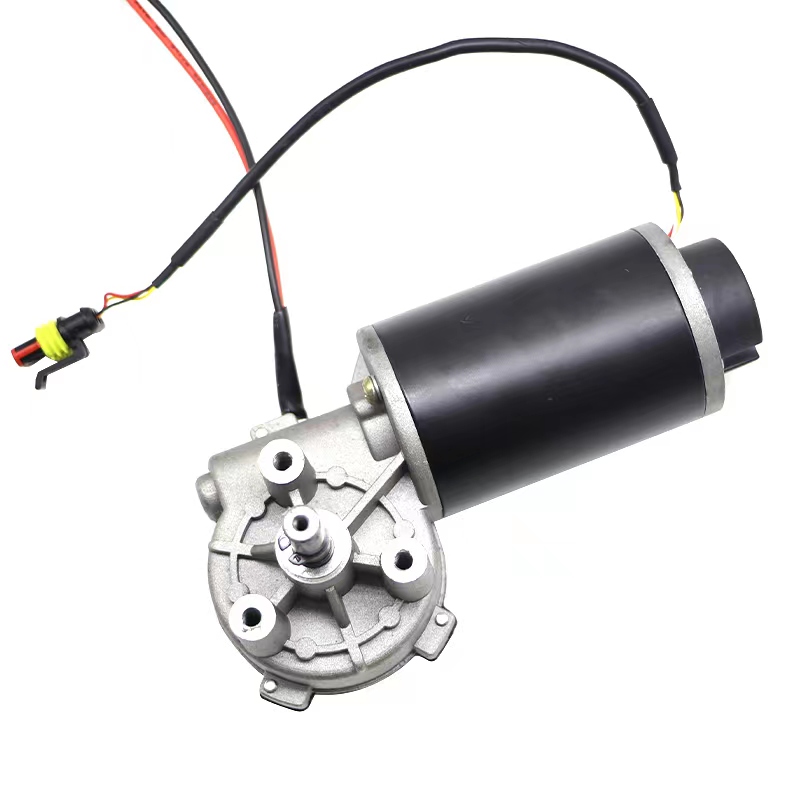

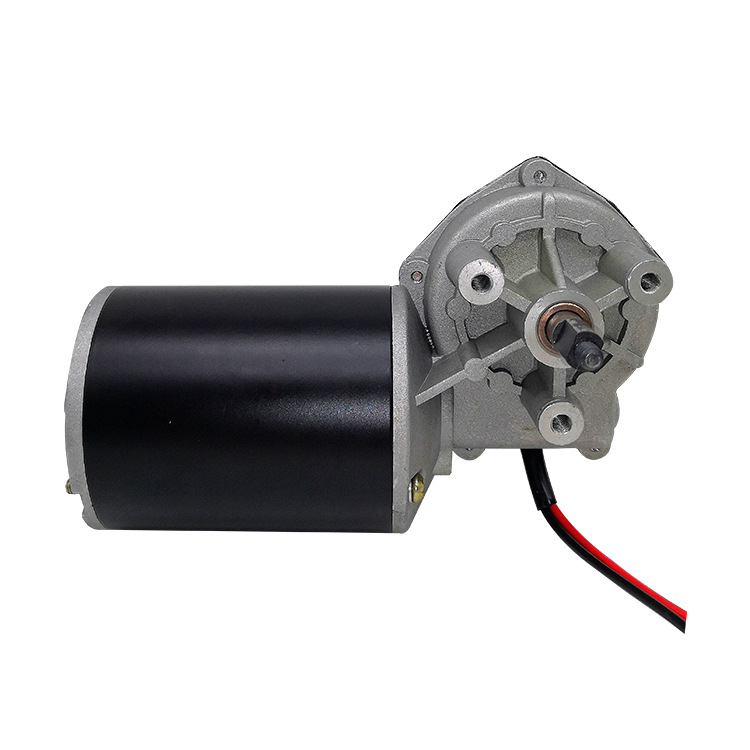

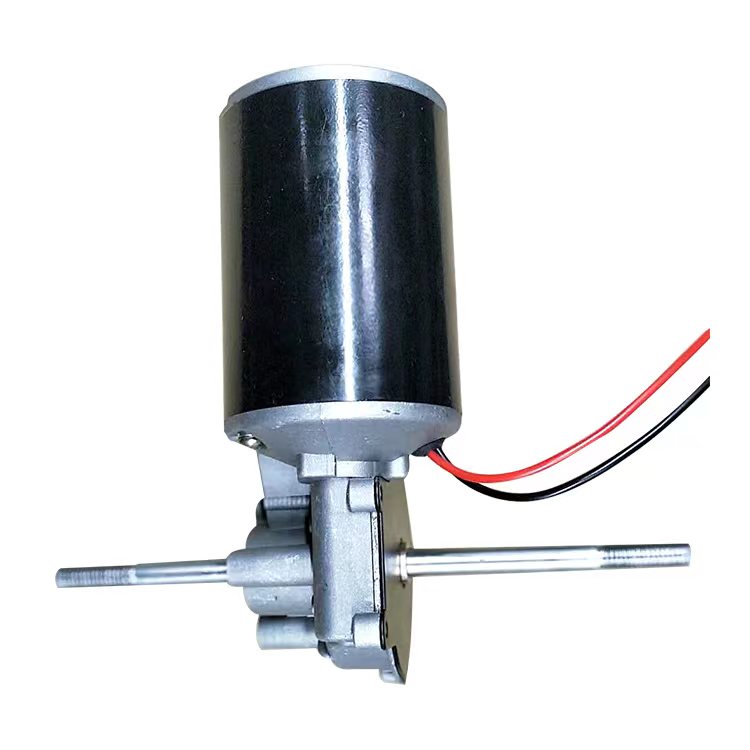

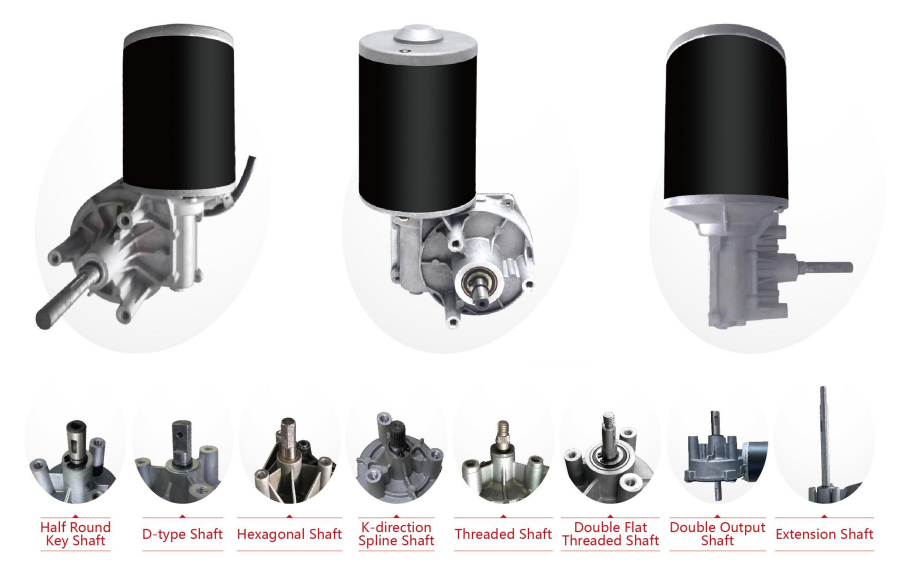

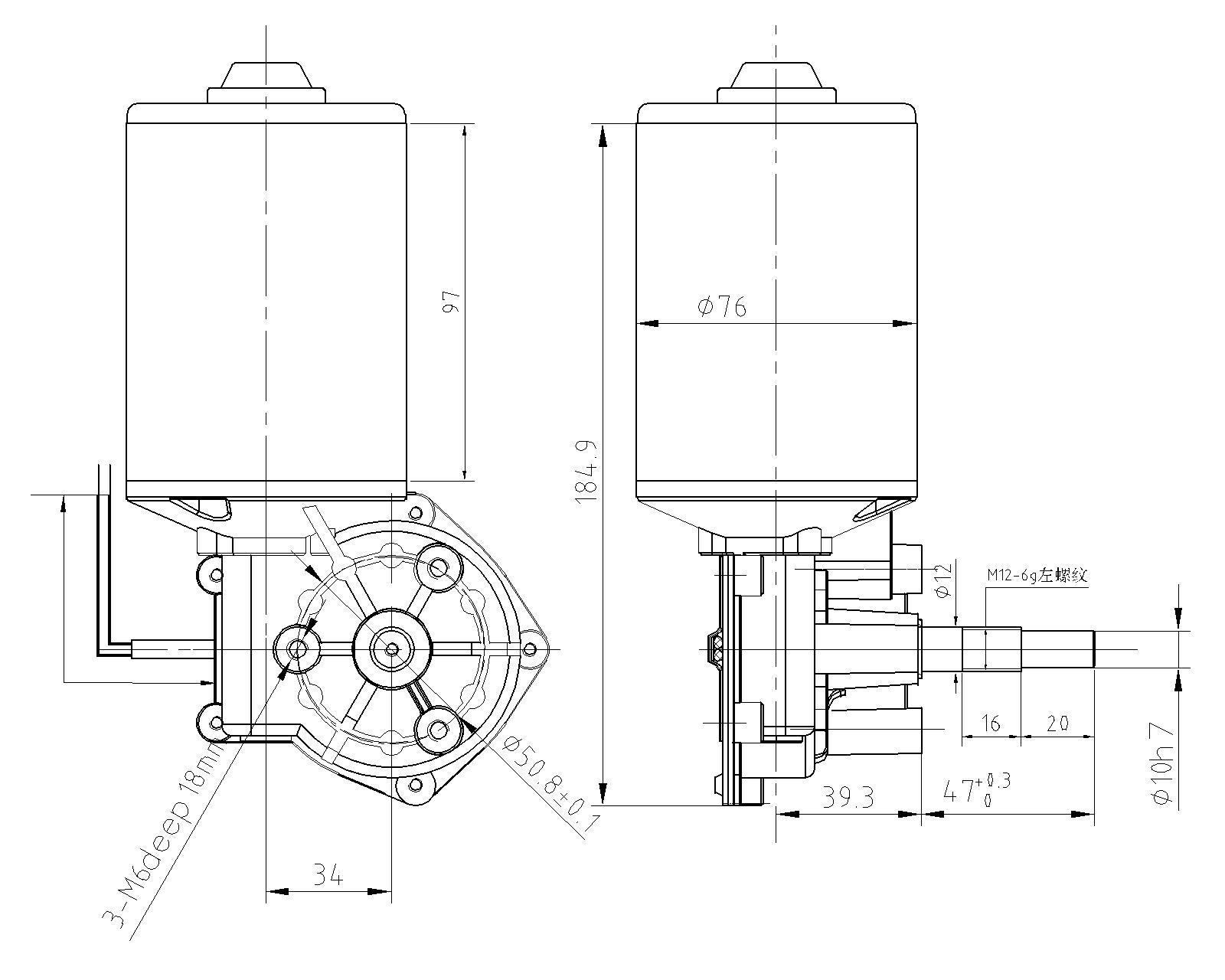

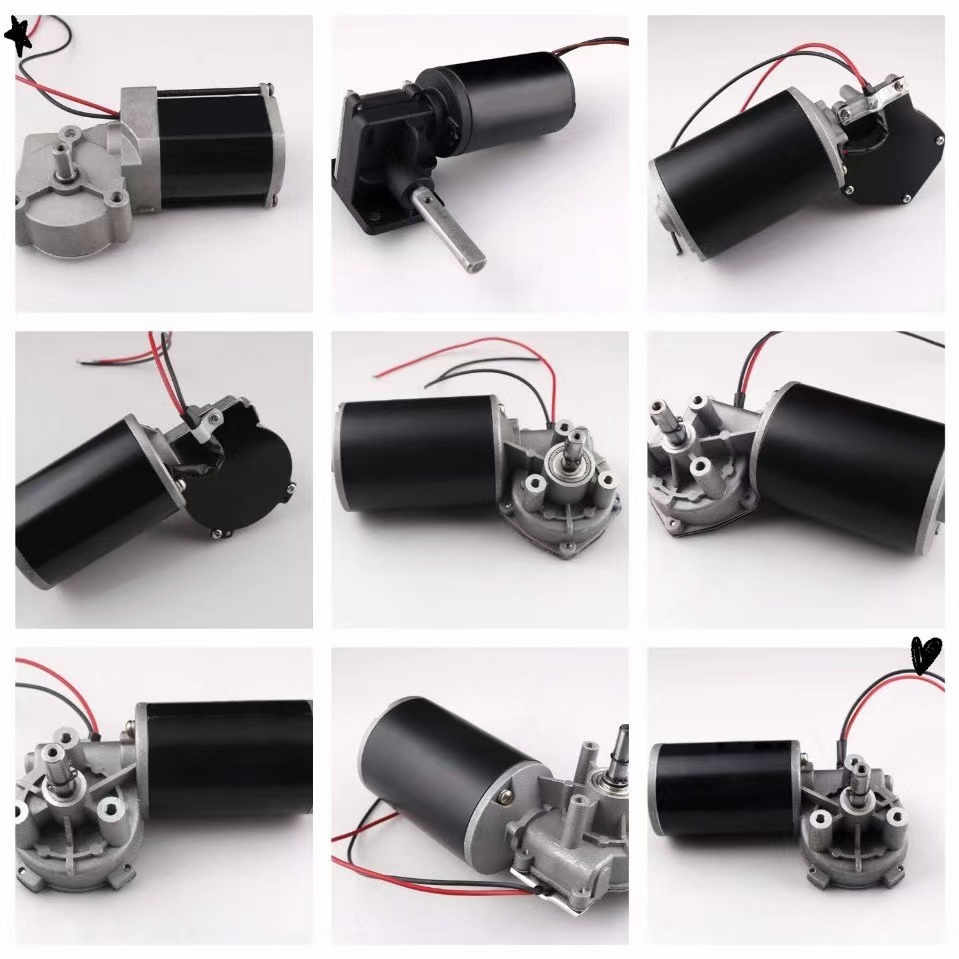

Let us to learn more about structure and funtion of the gear motors, This type DC gear motor frame have D63 D76 D80 D88.

The parameters of the motors above are for your reference, We can design and manufacture according to you required like voltage, power, speed, torque and dimension;

Voltage: 12v, 24v, 36v 48v 110v

Power: 30w-1000w

Output speed:15-200rpm

Speed sensor: Hall sensor, encoder, poto sensor

|  |  |  |

Gear Motor Applications

One common application of worm gear reducers is in conveyor systems. Conveyor belts are widely used in industries such as manufacturing, mining, and logistics to transport materials or products from one location to another. These systems require controlled and efficient movement, which can be achieved using a worm gear reducer.

The worm gear reducer consists of a worm, which is a cylindrical gear, and a worm wheel, also known as a worm gear. The worm gear is typically made of a soft material like bronze, while the worm is made of a harder material like steel. This combination allows for a smooth and efficient transfer of power.

In a conveyor system, the electric motor drives the input shaft of the worm gear reducer. As the worm rotates, it engages with the teeth of the worm wheel, causing it to rotate. The rotational motion of the worm wheel is then transmitted to the conveyor belt, resulting in the movement of materials along the conveyor.

The main advantage of using a worm gear reducer in this application is its ability to provide a high reduction ratio. The worm gear's design enables a large gear reduction in a compact size, making it suitable for applications where space is limited. Additionally, the self-locking nature of the worm gear prevents reverse motion, ensuring that the conveyor belt remains stationary when the motor is not running.

Overall, the integration of a worm gear reducer in a conveyor system allows for precise control, high torque, and efficient power transmission, making it an ideal choice for various industrial applications.

Application: Welding machine, electrical household, diamond machinery, office intelligent equipment, hotel leisure, automated machine and so on, there are many kinds of gear ratio for your demand

Why Use Worm Gear Motor?

High Reduction Ratio: Worm gear motors offer a high reduction ratio, meaning they can convert high-speed input from the motor into low-speed output with increased torque. This feature makes them suitable for applications that require high torque and low-speed operation, such as conveyor systems, winches, and lifting equipment.

Compact Design: Worm gear motors have a compact design due to the worm and worm wheel arrangement. This makes them ideal for applications where space is limited or where a compact and integrated power transmission solution is required.

Self-Locking Capability: Worm gear motors possess a self-locking characteristic, which means the output shaft cannot be back-driven by external forces when the motor is not running. This feature is beneficial for maintaining position or preventing unintentional movement in applications like gate openers, valve actuators, and hoists.

Smooth and Quiet Operation: The meshing of the worm and worm wheel in a worm gear motor results in a smooth and quiet operation. This makes them suitable for applications where noise reduction is important, such as in office equipment, medical devices, and household appliances.

High Efficiency: Worm gear motors can achieve high efficiency levels, especially when operating at higher reduction ratios. This efficiency is attributed to the sliding contact between the worm and the worm wheel, which minimizes friction and power losses.

Cost-Effective: Worm gear motors are often cost-effective compared to other types of gear motors. Their simple design, ease of manufacturing, and widespread availability contribute to their affordability, making them a popular choice for various applications.

Durability and Reliability: Worm gear motors are known for their durability and reliability. The meshing of the worm and worm wheel provides a large contact area, distributing the load evenly and reducing wear. This results in a longer service life and reduced maintenance requirements.

Gear Motor Solution Expert

At Biote motor, our motor experts are here to guide you to the ideal electric drive solutions for your unique application. Whether you need a motor to connect to your existing gearing or need help to create a customized gear motor for applications such as medical equipment, lawn mower, window door, swimming pool robotic cleaner, food & beverage equipment, and material handling equipment, we can help. Contact a member of our email sales@cnbiote.com or connect with us online.