2.5kw 48v 2800rpm Brushless DC Motor

Features:

1. Motor type: Brushless DC motor

2 .Gearbox: Worm gearbox, reducer

3. Voltage:48V

4. Speed:1200rpm,1500rpm

5. Torque: 8.5N.m

6. Shaft dia: 24mm

7. Direction: CW /CCW

8. Addition: Manual brake

9. Typical application: Electric vehicles, Industrial automation, boat propulsion, industry drive, transport robot Power tools, Medical equipment, Cleanning machine, HVAC systems

10. Customized service: Motor's performance parameter, Shaft type, Wires and connectors

- Information

- Video

- Downloads

2.5kw 48v 2800rpm Brushless DC motor

Brushless motors play a significant role in the design of track-guided flatbed carts, offering several advantages for efficient and reliable operation. Here are some key points about the use of brushless motors in track-guided flatbed cart designs:

Precise Speed Control: Brushless motors provide precise speed control, allowing track-guided flatbed carts to move smoothly along the designated path. This feature ensures accurate positioning and alignment of the cart, enhancing operational efficiency.

High Torque Output: Brushless motors offer high torque output, enabling track-guided flatbed carts to handle heavy loads with ease. The robust torque capabilities of brushless motors ensure effective traction and pulling power, making them suitable for transporting substantial payloads.

Energy Efficiency: Brushless motors are known for their high energy efficiency compared to brushed motors. They optimize power consumption, resulting in longer battery life and extended operation time for track-guided flatbed carts. This efficiency contributes to sustainable and cost-effective operation.

Low Maintenance: Brushless motors eliminate the need for brushes and commutators, which are wear-prone components in brushed motors. This design characteristic reduces maintenance requirements, minimizing downtime and maximizing productivity.

Compact and Lightweight: Brushless motors are typically compact and lightweight, making them well-suited for integration into the design of track-guided flatbed carts. Their small size and reduced weight contribute to space optimization and maneuverability of the carts.

Smooth and Quiet Operation: Brushless motors operate with minimal noise and vibration, ensuring a quiet and comfortable working environment. This feature is particularly beneficial in applications where noise reduction is essential, such as in indoor or noise-sensitive environments.

Durability and Longevity: Brushless motors are known for their durability, reliability, and extended lifespan. They are designed to withstand rigorous operating conditions, including continuous use and frequent starts and stops, making them suitable for the demanding requirements of track-guided flatbed cart applications.

In summary, the use of brushless motors in track-guided flatbed cart designs brings advantages such as precise speed control, high torque output, energy efficiency, low maintenance, compactness, smooth operation, and durability. These features contribute to the overall performance and reliability of track-guided flatbed carts in various industrial and logistical applications.

Brushless motors, also known as BLDC (Brushless DC) motors, are widely used in various applications due to their high efficiency, low maintenance, and compact size. Here are some common applications of brushless motors:

Electric vehicles: Brushless motors are used in electric cars, bikes, and scooters due to their high torque and efficiency. They are also used in hybrid vehicles as part of the powertrain.

Robotics: Brushless motors are commonly used in robotics for their precise control and high torque. They are used in robot arms, grippers, and other robotic components.

Industrial automation: Brushless motors are used in various industrial automation applications, such as conveyor systems, packaging machines, and assembly lines.

Aerospace: Brushless motors are used in aerospace applications due to their high power-to-weight ratio and reliability. They are used in drones, unmanned aerial vehicles (UAVs), and satellite systems.

Medical equipment: Brushless motors are used in various medical equipment, such as surgical tools, pumps, and ventilators, due to their precise control and low noise.

HVAC systems: Brushless motors are used in heating, ventilation, and air conditioning (HVAC) systems for their energy efficiency and low noise.

Consumer electronics: Brushless motors are used in various consumer electronics, such as drones, cameras, and power tools, due to their small size and high efficiency.

We also supply brushless dc motor with 12v 24v 48v. 72v.etc. if you need it. please contact us!

Higher Efficiency: Brushless motors achieve higher efficiency than brushed motors due to their design that eliminates the need for brushes, which reduces energy loss due to friction. This makes them ideal for applications where energy efficiency is critical.

Longer lifespan: Brushless motors have fewer moving parts, which results in less wear and tear, and thus a longer lifespan than brushed motors. This makes them ideal for applications where maintenance costs are a concern.

High torque density: Brushless motors can produce high torque at low speeds, which makes them ideal for applications that require high power and precise control.

Precise Control: Brushless motors provide precise control over speed, torque, and position, which makes them ideal for applications that require high accuracy and repeatability.

Low Noise: Brushless motors operate with lower noise levels than brushed motors, due to their design that eliminates the need for brushes and commutators.

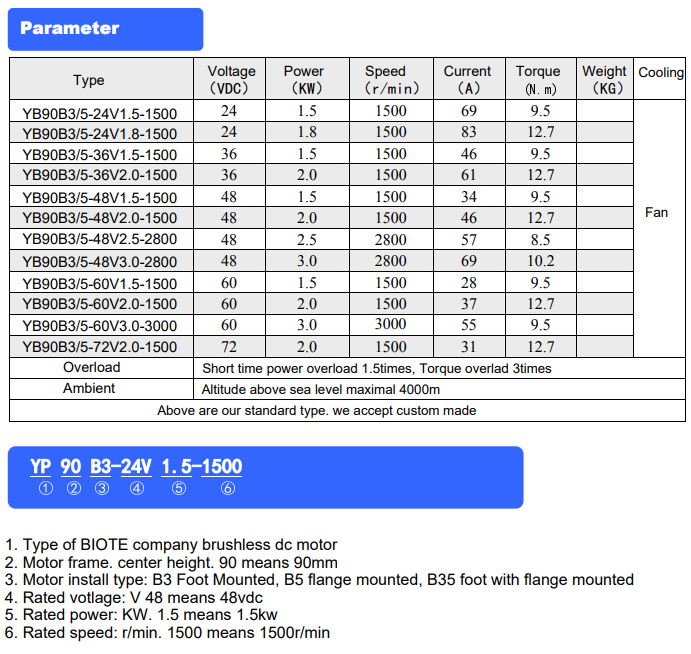

Biote Brushless DC motor

Brushless DC motors are widely used for many industrial applications as they have many advantages:

•High efficiency and high torque in a small diameter

•Low starting voltage,low rotor intertial, low noise,long lifetime

•wide range of speed control and steady working state with less inaccuracy

•The size according Y2 motor to design. easy install

Widely used in automation equipment such as Copier ,printing machinery,Engraving machine,packing machine,grinting machine,robot,machine tool,Milling machine,Sewing machine,Engraving machine,Medical apparatus,ATM machine ect.

The brushless DC motor are accept custom. please contact us send the power. voltage. speed and so on.We can give best ieda

This type of brushless dc motor alsop have other frame size

YB80 series Brushless DC motor

YB90 series Brushless DC motor

........

YB32 series Brushless DC motor

the power from 0.5kw- 15KW. .

Perfect ventilation cooling

Low power, electric-saving and money-saving

Reduce construction cost of the investment and enhance economic efficiency

We can also supply the brushless dc motor controller

This is brushless dc motor controller